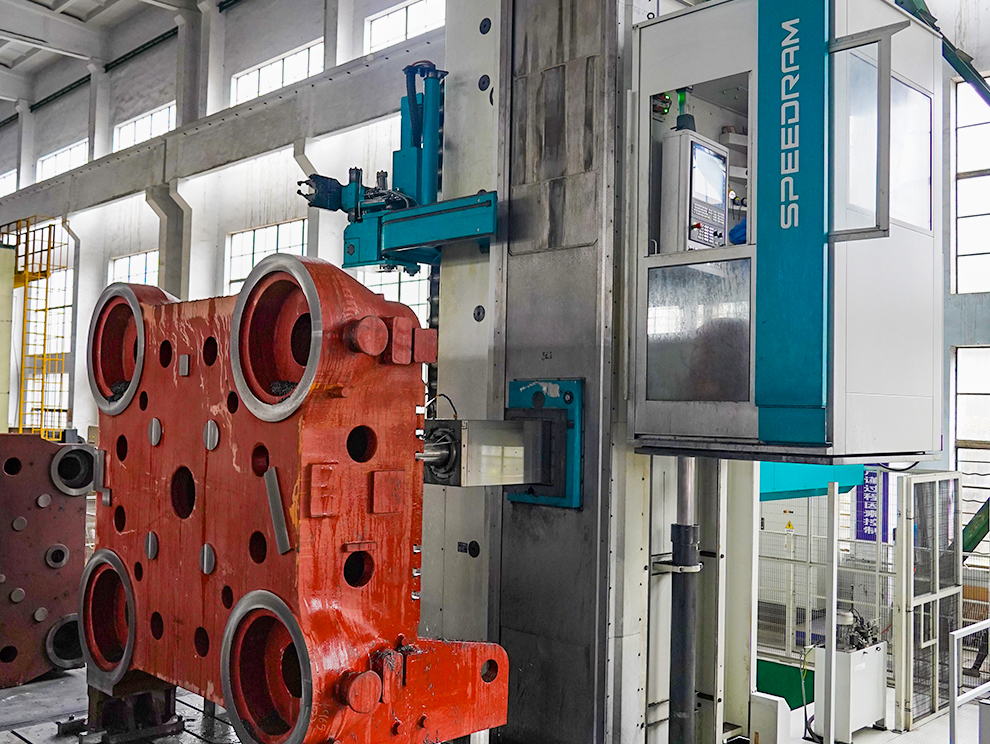

machining center

Quality is the life of Haida. In order to ensure product quality, the company has implemented ISO9001 quality management system for many years. The operation of the system is a long-term and effective means of quality assurance. The company implements the whole process quality control, including raw material quality management, process inspection, final inspection, review of unqualified products, analysis and treatment of product quality accidents and quality meeting. The workshop implements the system of "self inspection, mutual inspection and special inspection"; it strictly enforces the process discipline to ensure stable product quality; it flexibly uses scientific and reasonable mathematical statistics methods to analyze the causes of product quality fluctuation and control the quantity of unqualified products; it adheres to the system of "first inspection and inspection" to prevent the occurrence of batch scrapping. In the final inspection stage, the final inspector shall inspect all parts of the product according to the inspection methods formulated in the enterprise standard and the inspection items in the product acceptance record, and record them in the product acceptance record as the basis for product qualification. For qualified products, the final inspector shall fill in the product acceptance report, and the warehouse shall handle the warehousing procedures according to the report. Haida's quality objectives are as follows: the one-time acceptance rate of parts processing is ≥ 98%, the rework rate is controlled within 2%, and the scrap rate is & lt; 0.5%; the one-time inspection pass rate of finished product assembly is ≥ 98%, the return rate is & lt; 2%, and the final factory pass rate reaches 100%; the customer satisfaction rate is more than 95%, striving to be above 98%. In order to improve the quality of products, to produce and sell customers satisfied products. Haida spare no effort to constantly update the processing equipment and testing equipment, so that Haida's processing capacity, especially the manufacturing and processing capacity of large and super large injection molding machines and the quality assurance ability of products, ranks first in the industry.

news

service

contact

recruitment

中文站

news

service

contact

recruitment

中文站